Can You Put an 18V Battery on a 12V Motor – Here’s What Happens!

Using an 18V battery on a 12V motor might seem like a quick way to boost performance, but it can lead to serious issues. While you might see a temporary increase in speed, the motor will likely overheat and experience accelerated wear, reducing its lifespan significantly.

It’s generally safer to stick with the recommended voltage or use a voltage regulator to protect the motor and ensure long-term reliability.

Introduction:

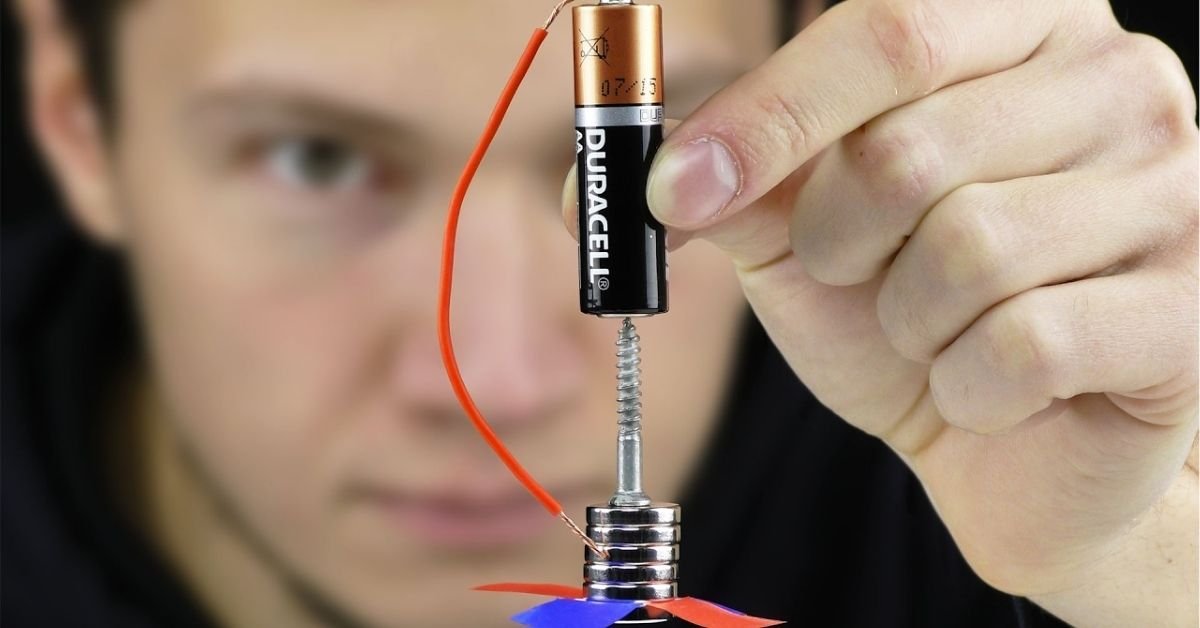

The question of whether you can put an 18V battery on a 12V motor is one that often sparks curiosity, especially among DIY enthusiasts. At first glance, it might seem like more voltage would mean more power and better performance.

However, the reality of voltage mismatch in electrical systems is far more complex. Understanding how voltage affects motor function, and the consequences of using incompatible power sources, is essential to ensuring your equipment operates efficiently and safely.

Understanding Voltage in Motors and Batteries:

The basics of voltage: What it means for motors and batteries

Voltage, often described as the electrical pressure that pushes current through a circuit, is fundamental in determining how electrical components operate. Motors and batteries are designed to work with specific voltage levels.

For a motor, the voltage is directly related to its performance, dictating the speed at which it operates and the amount of torque it produces. When a motor is rated for 12V, it means it is optimized to run efficiently with that specific voltage.

Batteries, on the other hand, store and supply this electrical energy, making voltage compatibility a critical factor in motor performance.

Why voltage compatibility matters in electrical systems:

Voltage compatibility is not just about matching numbers; it’s about ensuring that electrical components function within their designed limits. Motors are calibrated for a particular voltage, and exceeding this can lead to unintended consequences.

When you use an 18V battery on a 12V motor, the motor receives more electrical energy than it was designed to handle. This could lead to immediate gains in speed or torque, but it often comes at the cost of long-term durability and safe operation.

The risks of mismatching battery voltage with motor requirements:

The risks of mismatching voltage range from reduced efficiency to complete failure of the motor. An 18V battery forces the 12V motor to work harder than it should, causing overheating and excess wear.

These issues aren’t immediately visible, but over time, they manifest in reduced performance, mechanical strain, and eventual burnout. Beyond the motor, other components in your system, such as wiring or circuits, can also suffer damage from an overvoltage situation.

read also: Can a Bad Battery Cause O2 Sensor Code – Find Out Now!

What Happens When You Use an 18V Battery on a 12V Motor:

Overvoltage: How excessive power affects motor performance

Using an 18V battery on a 12V motor introduces the concept of overvoltage. When a motor is supplied with voltage beyond its capacity, it initially may perform faster or more powerfully. However, this increased output is not sustainable.

The motor’s components, such as the windings and bearings, are subjected to increased electrical stress, leading to inefficiencies. Instead of the motor running smoothly, you may experience fluctuations in speed, erratic behavior, and unexpected stalling.

Potential consequences: Overheating, wear, and damage to the motor:

One of the immediate concerns when using a higher voltage battery is overheating. Motors convert electrical energy into mechanical energy, and any excess electrical energy—such as that from an 18V battery—turns into heat.

The motor’s insulation may break down over time, leading to short circuits or a complete burnout. Additionally, continuous operation under such conditions causes mechanical wear. Bearings, gears, and other moving parts are not designed for the extra forces generated, leading to premature failure.

How the motor’s lifespan is impacted by using higher voltage:

Prolonged exposure to higher voltage significantly shortens the motor’s lifespan. A motor that might have lasted for years under normal conditions can be worn out in a matter of months when consistently overpowered.

Overheating, excessive friction, and the breaking down of internal components all contribute to a motor that degrades more rapidly than anticipated.

The Role of Voltage Regulators: Can They Help?

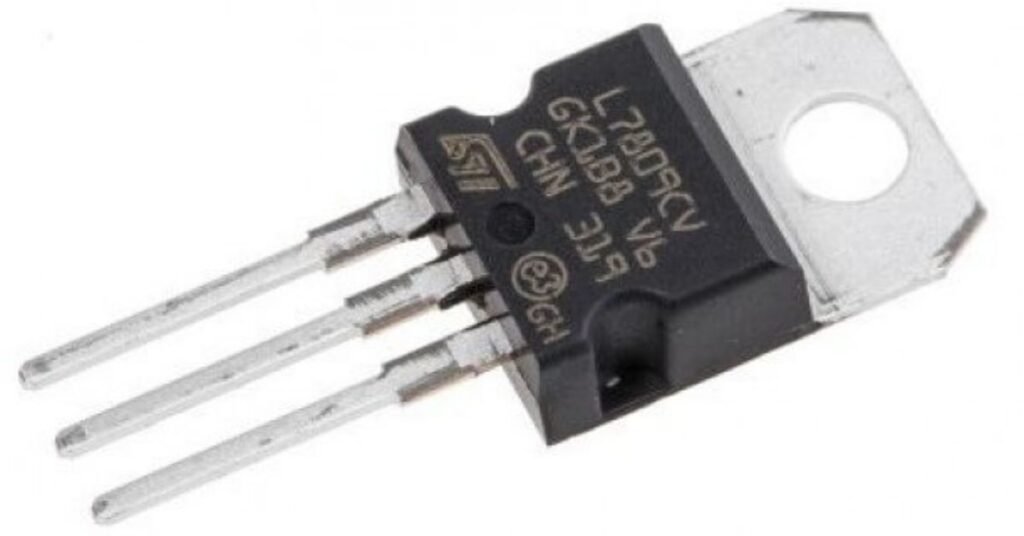

What are voltage regulators and how do they work?

A voltage regulator is an electronic device designed to maintain a consistent voltage level within a circuit, regardless of fluctuations in the power source.

When dealing with an overvoltage situation, such as using an 18V battery on a 12V motor, a voltage regulator can be used to step down the voltage. This ensures that the motor receives only the 12V it was designed to handle, protecting it from the harmful effects of overvoltage

Using a step-down voltage regulator to protect your 12V motor:

Step-down voltage regulators, also known as buck converters, reduce the input voltage to a desired lower level. In this case, an 18V battery could be used with a regulator to safely power a 12V motor.

This setup allows you to use batteries with higher voltages without compromising the motor’s safety. However, it’s important to ensure that the regulator is properly rated for both the input and output requirements to avoid inefficiencies or damage.

Limitations of voltage regulators when dealing with high-voltage inputs:

While voltage regulators provide a solution to the problem of mismatched voltage, they are not without limitations. Not all regulators can handle large voltage differences efficiently, and some may introduce heat into the system themselves.

Additionally, if improperly used or configured, a voltage regulator can fail, leaving your motor exposed to dangerous voltage levels. For DIY enthusiasts, it’s crucial to carefully select the right type of regulator to ensure safe operation.

read also: Can a Bad Battery Cause Stabilitrak Problems – Find Out Now!

Real-Life Scenarios: When People Use 18V Batteries on 12V Motors

Case studies of success and failure: What we can learn

There are countless real-world examples of people using higher-voltage batteries with lower-voltage motors. Some report short-term success, with their motors running faster and more powerfully than before.

However, these successes are often overshadowed by long-term failures, where motors burn out, overheat, or simply fail to operate after repeated use.

Temporary benefits vs. long-term damage:

In the short term, you may notice an improvement in performance when using an 18V battery on a 12V motor. However, these benefits are temporary.

The damage caused by excessive voltage—overheating, mechanical wear, and electrical strain—can lead to irreversible motor failure. For most applications, the short-term gain is not worth the long-term cost of replacing the motor.

Common DIY mistakes and myths:

A common DIY mistake is the belief that “more voltage equals more power.” While this is technically true, it’s an oversimplification that overlooks the nuances of electrical systems.

Another myth is that motors can be “pushed” beyond their rated capacity without significant consequences, which is rarely the case. Careful consideration of voltage compatibility is essential for any project involving electrical components.

Alternative Solutions: Powering a 12V Motor Safely

Choosing the right battery: Why voltage matching is important

The safest and most effective way to power a 12V motor is to use a 12V battery. Voltage matching ensures that the motor operates within its design parameters, preserving its longevity and performance. It eliminates the risk of overvoltage and avoids the need for additional components like regulators.

Other power sources and setups to consider:

If an 18V battery is the only available power source, consider using a series of smaller batteries to match the motor’s voltage. Alternatively, power supplies that offer adjustable voltage can be used to provide the exact power needed for the motor. This flexibility allows you to avoid the pitfalls of overvoltage while maintaining performance.

Modifying or upgrading your motor for higher voltage use:

In some cases, it may be possible to modify or upgrade your motor to handle higher voltages. This often involves reinforcing the motor’s insulation, upgrading components like bearings, and ensuring that the wiring is capable of handling the increased load. However, these modifications are complex and often costly, making them suitable only for specific applications.

read also: Why My ATV Dies When Battery Disconnected – Here’s the Fix!

Safety Precautions: What You Need to Know Before Experimenting

The dangers of overheating and motor failure:

When experimenting with higher voltage power sources, overheating is a primary concern. Heat not only damages the motor but can also lead to fires in extreme cases.

To mitigate these risks, ensure adequate ventilation, avoid prolonged operation under excessive voltage, and regularly monitor the motor’s temperature.

Protecting your equipment and ensuring safe operation:

Using protective devices like fuses or circuit breakers can help safeguard your motor and other components from electrical overloads.

Additionally, proper wiring and secure connections are essential to ensure that your system operates safely under varying loads.

When to consult a professional before making changes:

If you’re unsure about the safety or feasibility of using an 18V battery on a 12V motor, it’s always wise to consult an expert. Electrical systems can be complex, and the risks of overheating, equipment damage, or injury are significant. A professional can provide guidance on safe configurations and suggest alternative solutions.

FAQ’s

1. Can I use an 18V battery on a 12V motor?

While it’s possible, it’s not recommended. The 18V battery supplies more power than the motor is designed for, leading to overheating, mechanical wear, and potential long-term damage.

2. What happens if you overpower a 12V motor?

Overpowering a 12V motor causes overheating, reduced efficiency, and increased mechanical stress, significantly shortening its lifespan.

3. Can a voltage regulator help when using an 18V battery?

Yes, a step-down voltage regulator can reduce the voltage from 18V to 12V, protecting the motor from damage. However, it has limitations and must be properly configured.

4. What are the risks of using a higher voltage battery on a motor?

The main risks include motor burnout, overheating, and reduced performance over time, as well as potential damage to wiring and other system components.

5. Are there safer alternatives to power a 12V motor?

The safest option is to use a 12V battery. Alternatively, you can modify or upgrade the motor or use adjustable power supplies to match the voltage requirements.

Conclusion:

Using an 18V battery on a 12V motor may offer short-term benefits but leads to long-term damage and inefficiency. Voltage compatibility is critical in preserving motor performance and safety. When in doubt, always match voltage ratings or use protective devices like voltage regulators. Consulting a professional is often the best option for safe experimentation.

Read Also:

How to Troubleshoot a Car That Won’t Start Despite a New Battery – Here’s What to Do!

Can a Bad Alternator Stop Battery from Charging – Quick Fix Guide!

Why does my car battery light stay on even after replacement – Fix it now

What Size Alternator Do I Need for 2 Batteries – Your Complete Answer!

Post Comment